Showven Sparkular Fall Cold Spark Machine

In stock

Description / Showven Sparkular Fall Cold Spark Machine

Showven Sparkular Fall Machine - Indoor Firework Fountain Effects System

Showven Sparkular Fall indoor pyrotechnics Spark safe indoor display sparkler fountain.

The Showven Sparkular Fall FX system produces a fantastic, non-hazardous gerb effect that looks exactly like traditional fireworks or jet burst pyrotechnics.

- Sparks “waterfall” effects for professional stage

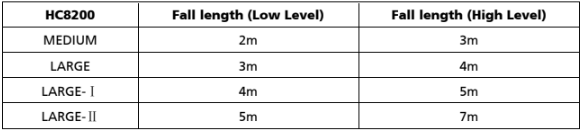

- Fall length from 2-7m with different HC8200

- Up to 13-21min effects duration after fill up

- Easy setup and teardown with multi locations

- DMX/Wireless remote control, can be started and stopped at any time

- Switchable effects mode (Low Level/High Level)

- *For safety use, please don’t touch sparks with hands or other flammable objects.

The effect is simply created using a Showven Sparkular Fall machine and a special granulated alloy, removing the need for gunpowder or traditional pyrotechnic techniques. The duration and height of the effect can be varied throughout a display, with sequences of 'dancing' sparks created to entertain audiences.

The Showven Sparkular Mini system operates at such cool temperatures; the sparks themselves are not flammable. The machines are also very smart and have multiple built-in safety protocols. You can control the start and stop of the effect at anytime, and the system is keycard locked so the machine cannot be abused in any manner. You now can control the time, height, volume this has never been achieved from a machine ever. This is beginning of a new technology to the world of stage of effects.

- No hazardous materials to transport or store on site.

- Much safer than using traditional pyrotechnics.

- No large safety or exclusion zones are required as the units produce cold fallout which is perfectly safe (the audience can pass their hands through the effect without any concern).

- Can be used in locations where fireworks and pyrotechnics are not permitted.

- Up to 15 minutes of effect can be produced from just one powder refill (equivalent to 1800 x 0.5 second pyrotechnic gerbs). This makes the system far more cost-effective.

- Low smoke output.

- Rigging time and crew requirement is dramatically reduced when compared to traditional pyrotechnics, again, making them far more cost-effective.

- Variable duration and height of the effects is achievable.

- The system is ideal for permanent installations or multiple date productions as they remove the need for re-loading.

- Remote control via DMX or the available dedicated Host controllers

SPECIFICATIONS - Sparkular Fall Machine

- Model: BT04/BT05

- Dimension: 196×208×192 mm

- Net Weight: 6.0 kg

- Input: 220 VAC (BT04) /110 VAC (BT05), 50/60 Hz

- Work Power: 500 W

- Work Temp.: -10 ℃~50 ℃

- Interface: Double DMX/AC power input interfaces

- Adaptable Truss Size: 40-60 mm

- FALL Lenght: 2 m-7 m, according to different HC8200

- Control: Wireless remote, DMX

- Packing size: Single unit 196×208×192 mm

- Packing size: 4 units 260 x 235 x 295 mm

- Packing size: Flightcase (6 unit) 545 x 495 x 320 mm

SPECIAL FEATURES - Fall Sparkular FX Machine

- Indoor / Outdoor usage

- Very low smoke, dissipates fast

- Sparkular effect from granules

- No smell from pyro

- Up to 3-4 minutes of shoot time per granules

- Easy set up multiple locations

- Height 2-2.5 meters

- Simple integration into musical synchronous shows

- Run up to 54 units in series VIA DMX cables

________________________________________________________________________________________

Showven Technologies Co., Ltd.

Thanks for choosing SPARKULAR® FALL, we wish it will sparks up your show.

Please read the following manual carefully before operating this product.

Δ Safety Instructions

\ Unauthorized repair are prohibited, it may cause serious incident.

\ Keep SPARKULAR® FALL dry and do NOT use in rain or snow.

\ Make sure lid of feeding hopper are well covered when use SPARKULAR® FALL.

\ Accidentally burning of consumable can only use sands to extinguish.

\ Consumable should keep away from moisture and stored in a dry sealed environment.

\ Check whether there is consumable aggregate in the output nozzle both before and after

each show, if any, please clean it up, or it will affect the firing effect, damage machine, even

cause serious incident.

\ The SPARKULAR® FALL power supply cable maximum allowed cascade of 6pcs (BT04) / 3pcs

(BT05), exceed connecting may result in damage or even cause fire.

\ For better heat dissipation, block the air intake and air outlet is prohibited.

\ Cover the output nozzle of SPARKULAR® FALL is forbidden, inspect the machine before each

show, making sure no objects or material will block the output nozzle.

\ Never touch the nozzle of SPARKULAR® FALL, danger of getting burnt.

\ Never touch the sparks which shooting out from the nozzle.

\ Make sure no staff, audience and flammable materials stays under the SPARKULAR® FALL.

Safety Distance

\ Keep audience and flammable material at a minimum distance of 3m from SPARKULAR®

FALL.

\ Make sure sparks shoot out from SPARKULAR® FALL can NOT touch any objects. And keep a

clearance with minimum 2m from the setting maximum effect length.

\ Human, animal or flammable materials are not allowed to close to the underside area where

hanging SPARKULAR® FALL.

\ In windy environment, increase the safety distance according to the wind direction and speed.

\ The safety zone area shifts accordingly when machine installed in tilt position. Please increase

the safety distance in the direction which machine tilt.

\ Sparks and consumables from the machine can lead to serious eye injury. Always wear safety

goggles when enter the safety zone.

Δ Description

SPARKULAR® FALL is hanging special effects equipment for indoor/outdoor use to generate

dazzling silver “waterfall” sparks effects. According to different usage scenarios, operator can

self define various types of “spark curtain” effects vary from 2m to 7m by use of different types

of HC8200.

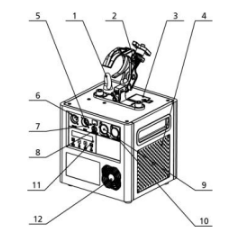

Δ Structure of SPARKULAR® FALL

1. Safety Loop

2. Clamp

3. Feeding Hopper Lid

4. Air Intake

5. DMX IN

6. DMX OUT

7. Power Switch

8. Fuse

9. Power IN

10. Power OUT

11. LCD Screen

12. Cooling Fan

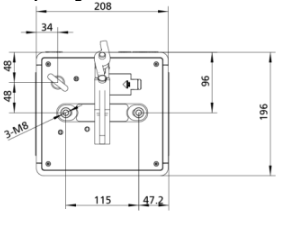

Schematic diagram of the top fixing hole

Δ Technical Specifications

\ MODEL: BT04/BT05

\ DIMENSION: 196×208×192mm

\ WEIGHT: 6.0kg

\ VOLTAGE: 220V(BT04)/110V(BT05), 50/60Hz

\ WORK POWER: 500W

\ EFFECT HEIGHT: 2-7m(according to HC8200 type)

\ INTERFACE: 3-pin XLR, POWER IN/OUT

\ CONTROL: DMX 2 channels, Wireless Remote

\ ADAPTABLE TRUSS SIZE: 40-60mm

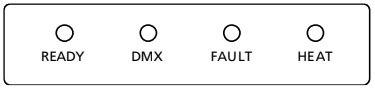

Δ Operation Panel

1. LED display area:

READY: Flash means machine is preparing, LED keeps on means ready to work

DMX: Flash means DMX signal is connected, light OFF means there is no DMX signal

FAULT: Light ON when error occurs

HEAT: Light ON when system is heating up

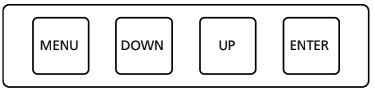

2. Control button area:

MENU Press to switch through menu, press and hold for 3s enter advanced menu

-: Parameters down

+: Parameters up

ENTER: Confirm and save parameters.

3. Bottom Indication Light

Off: Preheating not activated or machine is firing

Quick Flashing: Preheating

Long on: Preheated

Slow Flashing: Error warning

The indication light can be turned off in menu.

4. RFID area

Composite Ti with RFID card, swiping cards used to identify parameters and types of granules.

The RFID card is disposable, one card can only use one time.

Δ Interface

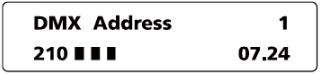

1. Main Interface

First line: Display DMX address is “1”

Second line: Display the present inner core temperature and the temperature progress bar;

displays remaining time is 7 minutes and 24 seconds.

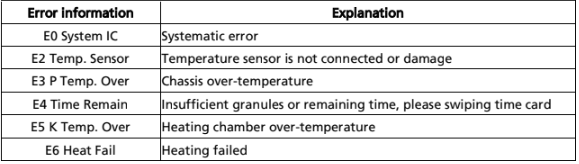

2. Error information

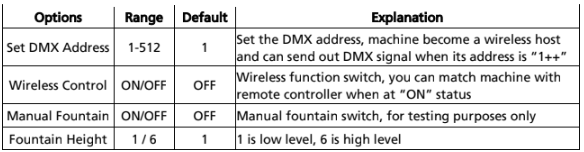

3. Setting Menu

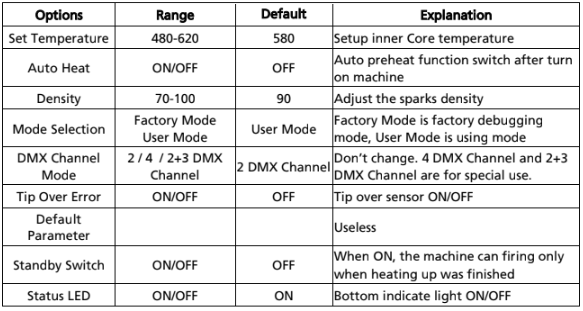

Press “MENU” to enter the Setting interface, press the “MENU” button to enter different

options until you return to the main interface

4. Advanced Menu

Press and hold “MENU” for 3s to enter the advanced setup interface, press MENU key to enter

different options, wait 3 seconds to return to the main interface

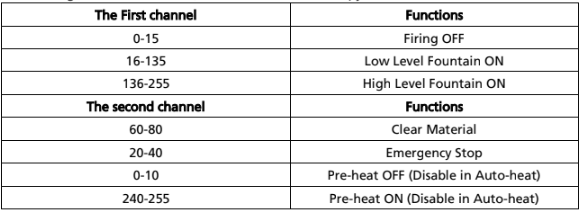

5. DMX mode

When using the DMX controller, SPARKULAR® FALL occupy 2 DMX channel

Δ Operation Guide

1. Check output nozzle of SPARKULAR®FALL

Check carefully the output nozzle of each machine, make sure the output nozzle is in good

shape and there is no powder aggregate.

2. Fill SPARKULAR®FALL

a) Open powder bags and fill the feeding hopper. Hopper capacity of SPARKULAR® FALL is

280g.

b) Choose correct consumable according to the hanging height and safety distance.

c) Make sure the lid of hopper is locked tight after filling.

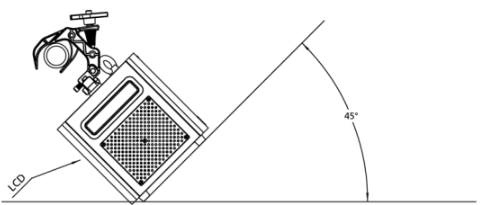

3. Install SPARKULAR®FALL

a) Vertical hanging installation is preferred for SPARKULAR® FALL. If need to installed

SPARKULAR® FALL in angles, please turn the Tip over to OFF status first, maximum firing

angle is 45 ° and can only be angled to the front side of the machine as below picture.

b) Make sure the machine is securely hanging on truss to avoid falling. An extra safety rope is

required for extra safety.

4. Connect Power / DMX cable

a) Connect a power cable to the POWER IN socket of SPARKULAR® FALL. Connect the other

end of power cable to the power source. Make sure power supply in consistent with the

rated voltage of the equipment, and the socket must well grounded.

b) If connect machine in sequence, please connect a power link cable to the POWER OUT of

previous machine, connect the other end of the power link cable to POWER IN of the next

machine.

c) The SPARKULAR® FALL power supply cable maximum allowed cascade of 6pcs (BT04) / 3pcs

(BT05). Do not connect exceed units to a single electrical circuit.

d) Power ON all SPARKULAR® FALL.

e) Assign DMX address for each unit of SPARKULAR® FALL. If use SHOWVEN host controller or

FXcommander to control the machine please allocate a unique DMX address for each unit

of machine.

If use remote controller to control SPARKULAR® FALL wirelessly, please set machine to

wireless ON status and match machine with remote controller. For DMX cable control please

execute below operations (f to h).

f) Connect a DMX cable to the DMX IN socket of first unit of SPARKULAR® FALL, connect the

male connector end of DMX cable to your DMX controller (FXcommander, HOST

CONTROLLER, light console etc).

g) Connect a DMX cable to the DMX OUT of previous machine, and the other end of to the

DMX IN of next machine. Connect all devices in series in this way.

h) Suggest to plug in a DMX terminator into the DMX OUT in last unit of machine to improve

signal reliability. Signal amplifier is required for long distance (>200m) DMX signal

transmission.

5. Activate SPARKULAR®FALL by swipe RFID card

a) Swipe an RFID card. Read the card as show below. SPARKULAR® FALL shows time remain if

read successfully.

b) SPARKULAR® FALL will report E4 when remaining time is less than 10 minutes.

c) Please note each RFID card come with 200g package HC8200 can increase single machine

20min working time, the maximum recharge time for SPARKULAR® FALL is 30min, when

time remain reached 30min, it can’t recharge anymore RFID card.

6. Programming and Firing

a) Programming SPARKULAR® FALL, set the firing height, firing sequences etc.

b) Heating up machine, it takes around 5min. it various according to the voltage and

environment temperature.

c) Make sure the prescribed safety zone is clear.

d) Suggest to clear material before firing.

e) Firing. In order to prevent overheat in the heating chamber and protect machine, the

maximum continuous firing time for SPARKULAR® FALL is 30s.

f) The operator should always have a clear view of the device, so that he/she can stop the

show immediately when there is danger.

g) Clear material for SPARKULAR® FALL for 5s after show, clear material will remove the

remaining particles from heating chamber. For angled installation please elongate clear

material time.

7. Turn off and Clean up

a) Power off SPARKULAR® FALL, allow SPARKULAR® FALL to cool down.

b) Disconnect all POWER and DMX cables. Remove the machine from truss carefully.

c) Empty the remaining HC8200 in hopper, and store the remaining HC8200 in a dry sealed

bottle for next time use. Never touch the output nozzle of SPARKULAR® FALL when empty

the hopper. DANGER OF GET BURNT!

d) Clean the surroundings to remove powder residues.

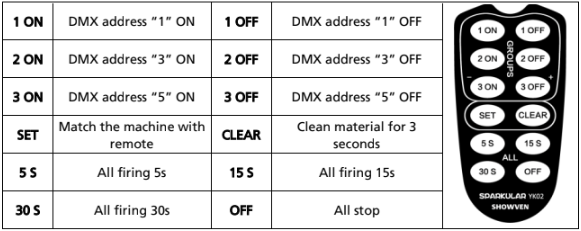

Δ Wireless Control Information

1. Wireless remote control mode:

When use wireless remote control, please unplug DMX cable connection on machine, set

Wireless Control at ON status, match the remote controller with machine, pull out the antenna

on remote controller.

NOTE:

a) When the indicator light becomes weak on the remote controller, please replace the

battery.

b) When the machine is occasionally not working, may be caused by interference, please press

the start button again.

c) Wireless control is easily influenced by interference, suggests to stay as close to machine as

possible when use remote controller, and machines cannot use metal shielding

3. Wireless host SPARKULAR®FALL mode (requires communication cables)

a) In occasion of strong interference, using the wireless host can avoid interference, ensure

stable control.

b) Set the first unit of SPARKULAR® FALL DMX address into “1++”, this machine address is “1”,

but it can also output DMX signal and turns into wireless host SPARKULAR® FALL.

c) Use communication cables to connect all SPARKULAR® FALL, the host SPARKULAR® FALL

will receive the signal from remote controller and transfer to all other SPARKULAR® FALL

via communication cable to realize stable signal transmission.

Δ Maintenance

a) Empty the feeding hopper before shipment of machine.

b) Empty the feeding hopper if long time not use, for high humidity environment we suggest

to empty feeding hopper after show.

c) Clear material both before and after the show.

d) Recommended to wash or replace the air intake filter every two months.

Δ Warranty Instructions

\ Sincere thanks for your choosing our products, you will receive quality service from us

\ The product warranty period is one year. If there are any quality problems within 7 days after

shipping out from our factory, we can exchange a brand new same model machine for you

\ We will offer free of charge maintenance service for machines which with hardware

malfunction (except for the instrument damage caused by human factors) in warranty period.

Please don't repair machine without factory permission

Below situations NOT included in warranty service:

\ Damage caused by use other type of consumable which is not originally from SHOWVEN®

\ Damage caused by improper transportation, usage, management, and maintenance, or

damage caused by human factors;

\ Disassemble, modify or repair products without permission;

\ Damage caused by external reasons (lightning strike, power supply etc.)

\ Damage caused by improper installation or use;

For product damage not included in warranty range, we can provide paid service.

Invoice is necessary when applying for maintenance service from SHOWVEN®

More Information

| Weight (kgs) | 6 |

|---|---|

| Voltage | 220 VAC 50/60HZ (110 VAC Available) |

| Model | Fall Machine BT04/BT05 |

| Length | 8.18" (208mm) |

| Height | 7.71" (196mm) |

| Width | 7.55" (192mm) |

| Size and Type | No |

| Linkable | Yes, via DMX |

| Power | 400 Watts |

| Range of Motion | No |

| Tank Height | No |

| Tank Width | No |

| Tank Weight | No |

| Tank Material | No |

| Tank Color | No |

| Tank Style | No |

| Tank Capacity | No |

| Tank Valve Outlet Orientation | No |

| Temperature Rating | 10-50℃ |

| LED Count | No |

| LED Color | No |

| LED Wattage | No |

| Reach | 3-15 feet (1-5m) |

| Nozzle Material | No |

| Pressure Rating | No |

| Warranty | 1 Year Warranty |

| Warranty (Tank) | No |