Showven Sparkular Cyclone Cold Spark Machine

In stock

Description / Showven Sparkular Cyclone Cold Spark Machine

Showven Sparkular Cyclone cold pyrotechnics display sparkler fountain.

The Showven Sparkular Cyclone FX system produces a fantastic, non-hazardous gerb effect that looks exactly like traditional fireworks or jet burst pyrotechnics.

Features and advantages for Sparkular Cyclone

- Impressive spark effect with adjustable height up to 10m

- Auto brake system, ensure immediate stop even in max output

- Neutrik PowerCON TRUE1, both 3-pin and 5-pin XLR connectors

- Reinforced and high strength stainless steel panel structure

- *For safety, please do NOT touch sparks with hands or other flammable objects.

Specifications for Sparkular Cyclone:

- Model: BT61/BT62

- Dimension: 457 x 370 x 280mm

- Weight: 27.0kg

- Voltage: 220V (BT61) / 110V (BT62), 50/60Hz

- Work power: 1700W

- Effect height: 6-10m adjustable

- Consumable consumption rate:75g/min

- Control: DMX

- Interface: Neutrik PowerCON TRUE1 IN/OUT,

- IP67 rated 3-pin & 5-pin XLR connectors

_____________________________________________________________________________________

Showven Technologies Co., Ltd.

Thanks for choosing SPARKULAR® Cyclone, we wish it will sparks up your show.

Please read the following manual carefully before operating this product.

Δ Safety Instructions

\ Unauthorized repair are prohibited, it may cause serious incident.

\ SPARKULAR® Cyclone can be used in rain, but after use please clean it, and store it at dry

environment.

\ Make sure lid of feeding hopper are well covered when use SPARKULAR® Cyclone.

\ Accidentally burning of consumable can only use sands to extinguish.

\ Consumable should keep away from moisture and stored in a dry sealed environment.

\ Check whether there is consumable aggregate in the output nozzle both before and after

each show, if any, please clean it up, or it will affect the firing effect or even damage

SPARKULAR® Cyclone.

\ Please be noted that there may sparks or remains fall to the ground when use HC8200 LARGE,

HC8200 LARGE I, HC8200 LARGE II, HC8200 LARGE III. Make sure there is no flammable

objects such as carpet on the ground with a radius of 3m close to the machine.

\ Maximum cascade of SPARKULAR® Cyclone is 2 units with one standard power cable. For

110V version SPARKULAR® Cyclone, we suggest each machine connect to power supply

directly. Otherwise it may damage the machine and even cause fire.

\ For better heat dissipation, block the air intake and air outlet is prohibited.

\ Cover the output nozzle of SPARKULAR® Cyclone is forbidden, inspect the machine before

each show, making sure no objects or material will block the output nozzle.

\ Never touch the nozzle of SPARKULAR® Cyclone, danger of getting burnt

\ Never touch the sparks which shooting out from the nozzle

\ Ensure that children, animals and unauthorized persons don’t have access to the

SPARKULAR® Cyclone.

Safety Distance

\ Keep audience and flammable material at a minimum distance of 3m from SPARKULAR®

Cyclone.

\ Make sure sparks shoot out from SPARKULAR® Cyclone can NOT touch any objects. And keep

a clearance with minimum 2m from the setting maximum effect height.

\ In windy environment, increase the safety distance according to the wind direction and speed.

\ The safety zone area changes accordingly when machine installed in tilt position. Please

increase the safety distance in the direction which machine tilt.

\ Sparks and consumables from the machine can lead to serious eye injury. Always wear safety

goggles when enter the safety zone.

Δ Description

SPARKULAR® Cyclone is a brand new product with SHOWVEN® original technology. It is with

amazing sparks effect up to 10m and equipped with auto brake system, ensure immediate stop

even in max output. SPARKULAR® Cyclone with waterproof design allows shows not

interrupted by rain. It is designed for the high demanding professional show market makes it

an ideal choice for large shows, concerts, music festival, outdoor events etc.

Δ Technical Specifications

\ Model: BT61/BT62

\ Dimension: 457 370 280mm

\ Weight: 25kg

\ Input: AC 220VAC-240VAC, 50/60HZ; 1700W

AC 100VAC-120VAC,50/60HZ; 1700W

\ Work Temp. : -20°C~50°C

\ Effect height: HC8200 LARGE III: 9-10m / HC8200 LARGE II: 8-9m

HC8200 LARGE I: 7-8m / HC8200 LARGE: 6-7m

\ Height adjustable: Yes, gear 1~10

\ Effect direction: Straight up

\ Hopper capacity: 500g

\ HC8200 consumption: 75g/min

\ Interface: NEUTRIK POWERCON TRUE1, 3-pin and 5-pin XLR

\ Control: DMX 2 channels

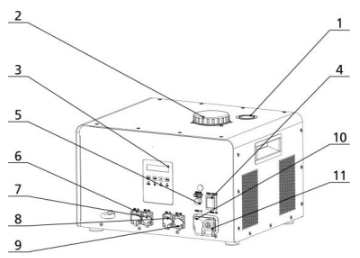

Δ Structure of SPRKULAR® Cyclone

1. Output Nozzle

2. Feeding Hopper Lid

3. LCD Screen

4. Power Switch

5. Fuse

6. 5-pin DMX IN

7. 5-pin DMX OUT

8. 3-pin DMX IN

9. 3-pin DMX OUT

10. POWER IN

11. POWER OUT

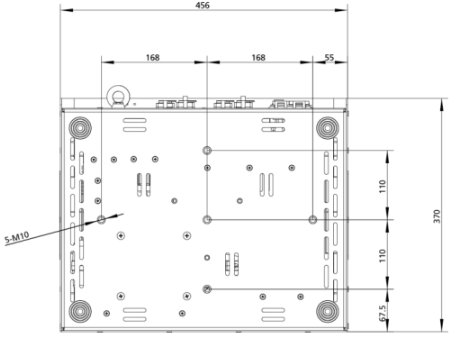

Diagram of Bottom Panel

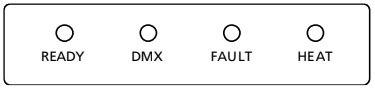

Δ Operation Panel

1. LED display area:

READY: Turns from flashing into long on, indicates that the machine is ready to work.

DMX: Flashing shows that DMX signal is connected; light OFF means there is no DMX signal

FAULT: Light ON when error occurs

HEAT: Light ON when system is heating up

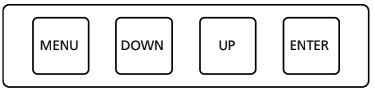

2. Control button area:

MENU: Press to switch through menu, press and hold for 3s enter advanced menu

DOWN: Parameter down

UP: Parameter up

ENTER: Confirm and save parameters

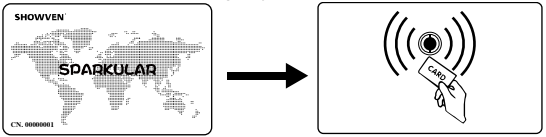

3. RFID area:

Composite Ti with RFID card, swiping cards used to identify parameters and types of granules.

The RFID card is disposable, one card can only use one time.

Δ Interface

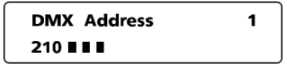

1. Main Interface:

First Line: shows DMX address

Second Line: shows inner temp. and temp. progress bar, as well as error info if available.

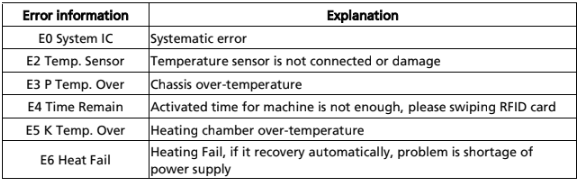

2. Error information

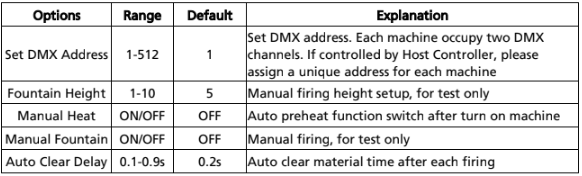

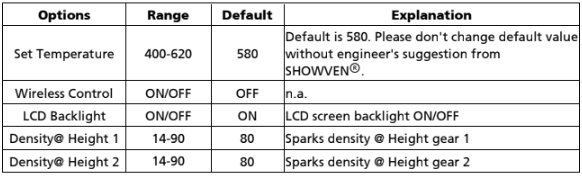

3. Setting Menu

Press “MENU” switch through setup menu.

4. Advanced Menu

Press “MENU” 3 seconds to enter the advanced setup interface, press MENU key to enter

different options, wait 3 seconds to return to the main interface.

For better performance of SPARKULAR® Cyclone, please don’t change the default value

without permission from SHOWVEN®

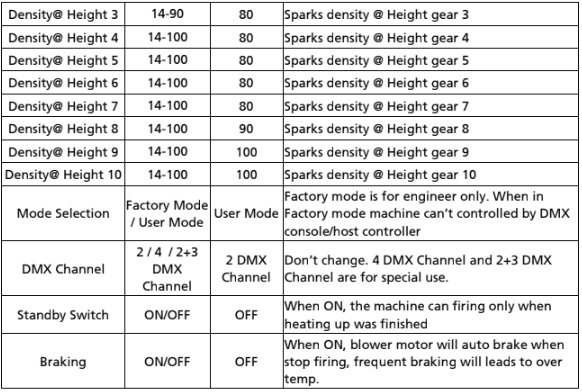

.5. DMX Control

SPARKULAR® Cyclone occupy 2 channels.

Δ Operation Guide

1. Install SPARKULAR®

Cyclone

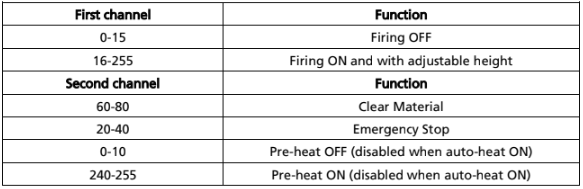

a) Horizontal installation is preferred for SPARKULAR® Cyclone. If need to installed

SPARKULAR® Cyclone in angles, maximum firing angle is 45 ° and can only be angled to the

right side as below picture.

b) Make sure the machine is securely installed to avoid tipping.

c) The safety zone area shifts accordingly when machine installed in tilt position. Please

increase the safety distance in the direction which machine tilt.

d) Check carefully the output nozzle of each machine, make sure the output nozzle is in good

shape and there is no powder aggregate.

2. Fill SPARKULAR®Cyclone

a) Open powder bags and fill the feeding hopper. Hopper capacity of SPARKULAR® Cyclone is

500g.

b) Choose correct consumable according to the application scenario.

c) Please be noted that there may sparks or remains fall to the ground. Make sure no

flammable material on ground in the safety zone.

d) Maximum effect height: HC8200 LARGE is 10m, HC8200 LARGE is 9m, HC8200 LARGE

is 8m and HC8200 LARGE 7m.

e) Make sure the lid of hopper is locked tight after filling.

3. Connect Power / DMX cable

a) Connect a power cable to the POWER IN socket of SPARKULAR® Cyclone. Connect the other

end of power cable to the power source. Make sure power supply in consistent with the

rated voltage of the equipment, and the socket must well grounded.

b) If connect machine in sequence, please connect a power link cable to the POWER OUT of

previous machine, connect the other end of the power link cable to POWER IN of the next

machine.

c) The Maximum cascade of SPARKULAR® Cyclone is 2 units with one standard power cable.

For 110V version SPARKULAR® Cyclone, we suggest each machine connect to power supply

directly. Do not connect exceed units to a single electrical circuit.

d) Power ON all SPARKULAR® Cyclone.

e) Assign DMX address for each unit of SPARKULAR® Cyclone. If use SHOWVEN host controller

or FXcommander to control the machine please allocate a unique DMX address for each

unit of machine.

f) Connect a DMX cable to the DMX IN socket of first unit of SPARKULAR® Cyclone, connect

the male connector end of DMX cable to your DMX controller (FXcommander, HOST

CONTROLLER, light console etc).

g) Connect a DMX cable to the DMX OUT of previous machine, and the other end of to the

DMX IN of next machine. Connect all devices in series in this way.

h) Suggest to plug in a DMX terminator into the DMX OUT in last unit of machine to improve

signal reliability. Signal amplifier is required for long distance (>200m) DMX signal

transmission.

4. Activate SPARKULAR®Cyclone by swipe RFID card

a) Swipe an RFID card. Read the card as show below. SPARKULAR® Cyclone shows time remain

if read successfully.

b) SPARKULAR® Cyclone will report E4 when remaining time is less than 10 minutes.

c) Please note each RFID card come with 200g package HC8200 can increase single machine

10min working time, the maximum recharge time each time for SPARKULAR® Cyclone is

30min, when time remain reached 30min, it can’t recharge anymore RFID card.

5. Programming and Firing

a) Programming SPARKULAR® Cyclone, set the firing height, firing sequences etc.

b) Heating up machine, it takes around 5min. it various according to the voltage and

environment temperature.

c) Make sure the prescribed safety zone is clear.

d) Suggest to clear material before firing.

e) Firing. In order to prevent overheat in the heating chamber and protect machine, the

maximum continuous firing time for SPARKULAR® Cyclone is 30s.

f) The operator should always have a clear view of the device, so that he/she can stop the

show immediately when there is danger.

g) Clear material for SPARKULAR® Cyclone for 5s after show, clear material will remove the

remaining particles from heating chamber. For angled installation, please elongate clear

material time.

6. Turn off and Clean up

a) Power off SPARKULAR® II, allow SPARKULAR® Cyclone to cool down.

b) Disconnect all POWER and DMX cables.

c) Empty the remaining HC8200 in hopper, and store the remaining HC8200 in a dry sealed

bottle for next time use. Never touch the output nozzle of SPARKULAR® Cyclone when

empty the hopper. DANGER OF GET BURNT!

d) Operators can use handheld vacuum cleaner to empty the feeding hopper. Do make sure

the machine was cool down when clean it. Do NOT use high-power vacuum cleaners to

avoid hot consumables being sucked into the vacuum cleaner from the heating chamber

and cause fire.

e) Clean the surroundings to remove powder residues.

Δ Maintenance

1. Empty the feeding hopper before shipment of machine.

2. Empty the feeding hopper if long time not use, for high humidity environment we

suggest to empty feeding hopper after each show.

3. Clear material both before and after the show.

Δ Warranty Instructions

\ Sincere thanks for your choosing our products, you will receive quality service from us

\ The product warranty period is one year. If there are any quality problems within 7 days after

shipping out from our factory, we can exchange a brand new same model machine for you

\ We will offer free of charge maintenance service for machines which with hardware

malfunction (except for the instrument damage caused by human factors) in warranty period.

Please don't repair machine without factory permission

Below situations NOT included in warranty service:

\ Damage caused by use other type of consumable which is not originally from SHOWVEN®.

\ Damage caused by improper transportation, usage, management, and maintenance, or

damage caused by human factors;

\ Disassemble, modify or repair products without permission;

\ Damage caused by external reasons (lightning strike, power supply etc.)

\ Damage caused by improper installation or use;

For product damage not included in warranty range, we can provide paid service.

Invoice is necessary when applying for maintenance service from SHOWVEN®